Discover the future of automation with

Automation X - your premier partner for

cutting-edge robot automation services.

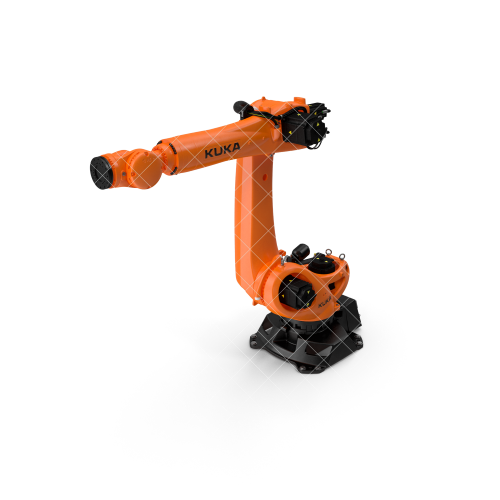

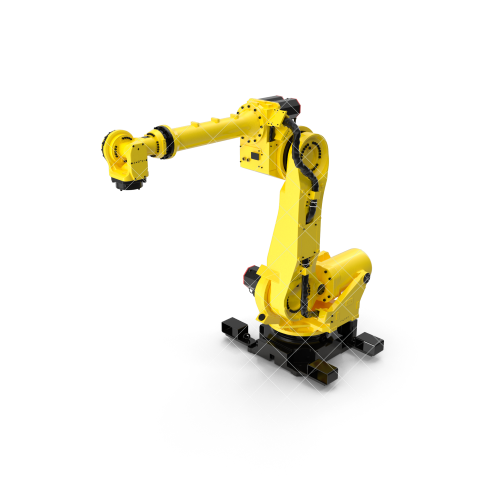

Industrial robots play a vital role in automating arduous and repetitive tasks, especially in scenarios where optimising processes is crucial for sustained reductions in operational costs and heightened worker safety.

An industrial robot is purpose-built to automate demanding production tasks, such as those encountered in a constantly moving assembly line. These robust and sizable robots are strategically stationed in fixed locations within an industrial facility.

At Automation X, as part of our comprehensive process assessment, we pinpoint areas where integrating robots can provide maximum value. Our platform-independent approach ensures that each client receives precisely tailored robotic solutions from the most suitable robotics partners for their unique requirements.

Industrial robots are tried-and-tested solutions, having demonstrated their effectiveness across various industries over extensive periods.

These robots streamline processes that historically consumed significant time and resources. They emulate human motion while harnessing machine strength, precision, and speed.

Unlike humans, robots don't need rest, contributing to a more scalable and efficient production line.

In an era of labour shortages, leveraging robotic solutions as intelligent resources can empower existing staff by freeing them up for more value-added tasks.

Safety levels rise as employees are relieved from exposure to high volumes of hazardous and repetitive tasks. Industrial robotics aim to optimise production lines for increased agility and adaptability to specific business needs.

With high repeatability and the elimination of human error, industrial robots contribute to the production of superior quality products adhering to stringent standards. This also reduces the time needed for quality control and inspection.

The equation is simple—higher quality products combined with reduced time requirements equals an increased profit margin.

Stand out from competitors by investing in the future of streamlined process lines, demonstrating a commitment to innovation and efficiency.

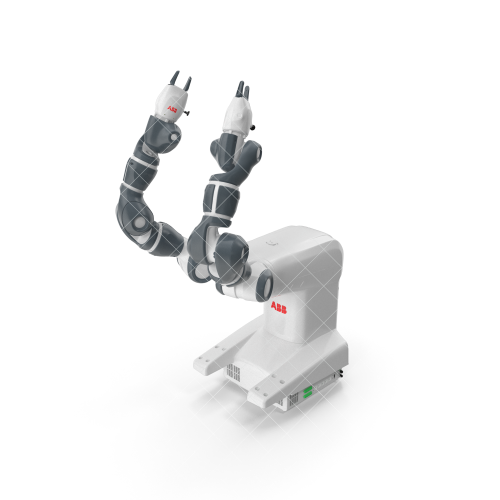

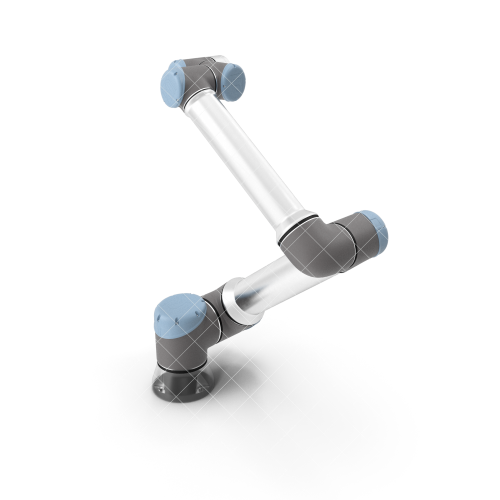

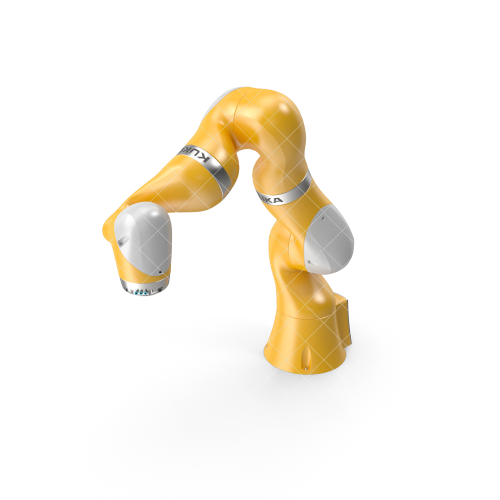

Collaborative robots empower manufacturers with the advantages of advanced robotic automation, sidestepping the additional complexities associated with traditional industrial robots, such as intricate programming, the need for shielded work cells, and limited task flexibility.

This is precisely why we recommend preliminary discussions with us before implementation, allowing exploration of diverse robotic options. As a provider of platform-independent automation solutions, we ensure the selection of suitable robot types from the most fitting manufacturers for the specific components of your intended process line automation.

Collaborative robots significantly contribute to diminishing wastage, minimising human error, and enhancing scalability, all leading to streamlined operational costs.

Processes undergo heightened efficiency with reduced margins for error, resulting in elevated quality and augmented production. Our versatile team effortlessly navigates automation projects from conception to fruition.

Cobots, by nature, offer unmatched flexibility, effortlessly integrating tasks and facilitating the execution of diverse activities daily.

Collaborative robots boast precision with repeatability down to 0.1 mm, ensuring consistent actions without deviation. Tasks, such as screw tightening, maintain uniform torque and speed for reliability.

Given their compact size and adaptable nature, Collaborative Robots boast rapid implementation, sometimes achieving operational status within an hour in certain scenarios.

Simplified programming and implementation compared to larger traditional industrial robots translate to a swift return on your capital investment.

Empowering skilled staff by freeing them from monotonous, repetitive tasks contributes to increased job satisfaction, aligning with our commitment to a more fulfilling work environment.

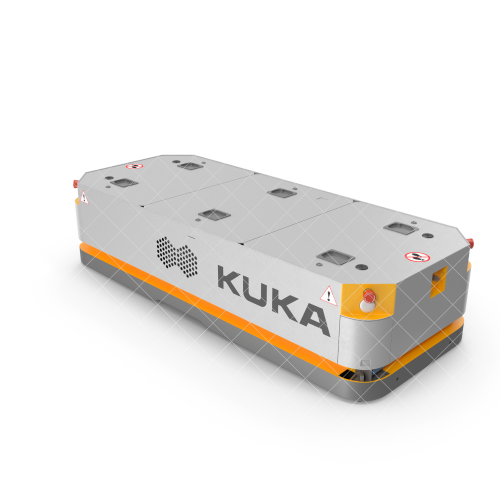

Robotic solutions like Automated Guided Vehicles (AGVs) operate along predetermined paths marked on the floor, utilising advanced sensors and technology to navigate and avoid obstacles effectively.

Autonomous Mobile Robots (AMRs), also recognised as Autonomous Intelligent Vehicles (AIVs), stand out for their unparalleled flexibility compared to AGVs. Unlike AGVs confined to predetermined paths, AMRs dynamically navigate through environments, adapting routes on the fly based on real-time conditions.

To ensure optimal robotic integration, we strongly recommend a collaborative approach with us before implementation. As a provider of platform-independent automation solutions, we guarantee the selection of suitable robot types from reputable manufacturers tailored to the specific automation needs of your process line.

AGVs and AMRs present a straightforward and effective solution for intra-facility product movement, outperforming conventional production methods.

Operating autonomously, AGVs and AMRs significantly diminish the risk of accidents resulting from human error, proving particularly advantageous in environments unsuitable for human presence.

AGVs and AMRs operate continuously, 24/7, contributing to heightened productivity and reduced downtime in manufacturing or warehousing operations.

AMRs demonstrate exceptional flexibility, swiftly reprogramming for various tasks. This adaptability allows businesses to promptly respond to evolving customer demands and production requirements.

Implementing AGVs or AMRs translates into substantial cost savings, reducing reliance on human labour and mitigating the potential for costly mistakes or accidents.

AGVs and AMRs, programmed with precision, elevate quality control and minimise waste in production processes.

Outfitted with cutting-edge sensors and technology, AGVs and AMRs collect invaluable data on production processes, empowering businesses to identify areas for improvement and optimise operations.

Simulation is a powerful tool that replicates real-world scenarios in a controlled virtual environment, providing invaluable insights and testing capabilities.

Virtual scenarios allow for the identification of potential challenges and the exploration of various solutions before actual implementation, mitigating risks and optimising processes.

Here at Automation X, we advocate for a collaborative approach with our clients during the simulation phase. As a platform-independent provider of automation solutions, we ensure the selection of the most suitable simulation tools tailored to your specific needs.

Simulation helps foresee potential challenges and bottlenecks, allowing for proactive problem-solving before actual implementation.

Identifying and rectifying issues in a virtual environment significantly reduces the financial impact of errors or inefficiencies in the real world.

Through simulation, different scenarios can be tested and fine-tuned to achieve the most efficient and effective processes.

Simulation provides a wealth of data and insights, enabling informed decision-making based on a comprehensive understanding.

By addressing issues in the virtual realm, simulation accelerates the development and implementation phases, saving valuable time.

Simulation allows for the exploration of various design options, facilitating the selection of the most optimal solution for your specific requirements.

Continuous simulation and analysis contribute to an iterative improvement process, ensuring ongoing optimisation and adaptation to your ever changing business needs .

Collaborating with Automation X on simulation not only allows for a smoother transition to real-world implementation but also ensures that the chosen simulation tools align seamlessly with your unique automation goals.

At Automation X, we take pride in offering comprehensive consultancy services encompassing various engineering activities throughout the automation process. Our expertise extends to a diverse range of services, including but not limited to Design, Project Management, Simulation, and Process Engineering.

External consultants bring an unbiased external perspective, offering fresh insights and innovative solutions that may be overlooked internally.

Outside consultants often possess specialised knowledge and skills honed through diverse experiences, providing a depth of expertise that might not be available in-house.

Engaging external consultancy services can be cost-effective compared to maintaining a dedicated in-house team for specialised tasks. It allows businesses to access expertise without the overhead costs.

Outsourcing consultancy ensures optimal resource utilisation, allowing your internal team to focus on core business functions while our experts handle specific tasks.

External consultants offer flexibility in terms of project duration and scale. You can engage them for specific projects without long-term commitments, adapting to your changing needs.

External consultants often bring exposure to industry best practices and the latest trends, ensuring that your business benefits from the most advanced and effective strategies.

Consultants are equipped to initiate projects quickly, leveraging their expertise and established methodologies to streamline processes and achieve results efficiently.

External consultants provide an added layer of risk mitigation. Their objective viewpoint helps identify potential risks early, allowing for proactive measures to minimise any impact that may be detremintal to your business.

Established consultancy firms often have extensive networks and industry connections, providing additional resources and potential partnerships that can benefit your business.

Outsourcing consultancy services allows your business to focus on its core competencies, while experts handle specialised tasks, leading to overall efficiency and productivity gains.

Choosing Automation X as your external consultancy partner ensures that you not only tap into these advantages but also benefit from our platform-independent approach and commitment to tailoring solutions to meet your unique automation needs.